Description

FOR PRECISE CONTROL OF NORMAL TO HIGH CONSTANT VOLUME FLOW RATES

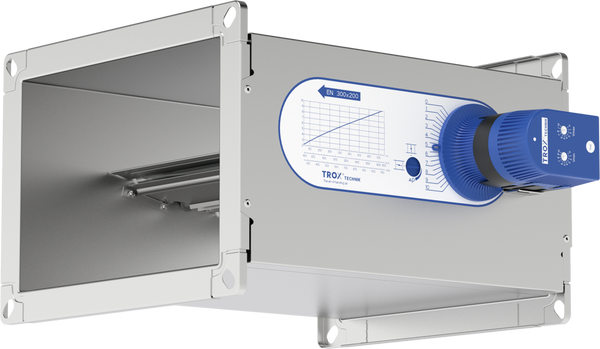

Rectangular, mechanically self-powered air terminal units for supply and extract air systems with constant air volume flows

- Suitable for volume flow rates up to 7416 cfm

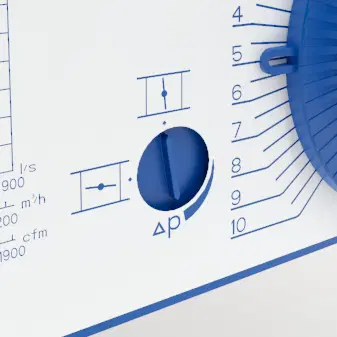

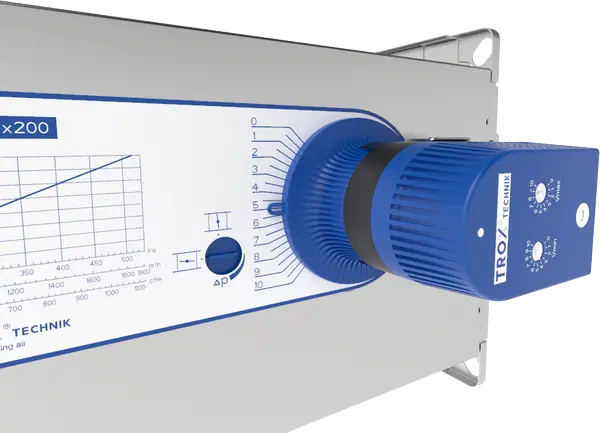

- Volume flow rate adjustment from outside by rotary knob

- Easy retrofitting of an actuator for volume flow setpoint adjustment

- High control accuracy

- No on-site test measurements required for commissioning

- Casing air leakage to EN 1751, class C

- Visual display of the damper blade position for operating point optimization

Optional equipment and accessories

- Acoustic cladding for the reduction of case-radiated noise

- Secondary silencer Type TX for the reduction of air-regenerated noise

- Hot water heat exchanger Type WT for reheating the airflow

- Actuator for setpoint value switching or steady operation

Application

- Rectangular CAV terminal units for supply or extract air volume flow control in constant volume flow systems

- Mechanical self-powered volume flow control without external power supply

- Simplified project handling by ordering based on nominal size

Special features

- Setting of the volume flow setpoint from the outside by rotary knob

- High control accuracy of the set volume flow rate

- Correct operation even under unfavorable upstream conditions

- Visual display of the damper blade position for operating point optimization

- Easy retrofitting of an actuator for volume flow setpoint adjustment

Nominal sizes

- 19 nominal sizes from 8 × 4 to 24 x 24 in

Variants

- EN: Air terminal units

- EN-D: Air terminal units with acoustic cladding

- Air terminal units with acoustic cladding and/or secondary silencer type TX for high acoustic requirements

Construction

- Galvanized sheet steel

- P1: Powder-coated, silver grey (RAL 7001)

Parts and characteristics

- Air terminal unit ready for commissioning

- Damper blade with low-friction bearings

- Bellows for vibration damping

- Cam plate with leaf spring

- Rotary knob pointer and scale for adjusting the flow rate setpoint

- Each air terminal unit is tested in the factory on a special ventilation test rig

- Visual display of the damper blade position for operating point optimization

Attachments

- Min/Max actuators: Actuators for switching between minimum and maximum volume flow rate setpoint values

- Variable actuators: actuators for variable volume flow or for switching volume flow setpoints

- EN with actuator only up to H = 12 in

Useful additions

- Rectangular casing

- Secondary silencer Type TX

- Heat exchangers Type WT

Construction features

- Rectangular casing

- Flanges on both ends, suitable for duct connections

- Air terminal units from H = 400 mm as double version (2 dampers with separate setting scales)

- Acoustic cladding cannot be retrofitted

Materials and surfaces

- Galvanized sheet steel construction

- Casing and damper blade made of galvanized sheet steel

- Leaf spring made of stainless steel

- Polyurethane bellows

- Plain bearings with PTFE coating

- Cam plate and adjusting unit made of galvanized sheet steel

- Powder-coated construction (P1)

- Variant with acoustic cladding (-D)

- Acoustic cladding made of galvanized sheet steel

- Rubber seal for the insulation of structure-borne noise

- Lining made of mineral wool

Mineral wool

- Acc. to EN 13501, fire rating class A1, non-combustible

- RAL quality mark RAL-GZ 388

- Non-hazardous thanks to high biosolubility according to the German Ordinance on Hazardous Substances and Note Q of the European Regulation (EC) No. 1272/2008

Standards and guidelines

Meets the hygiene requirements of

- EN 16798, Part 3

- VDI 6022, Sheet 1

- DIN 1946, Part 4

- For further standards and guidelines, please refer to the hygiene certificate

Casing air leakage

- EN 1751, Class C

Maintenance

- Maintenance-free as construction and materials are not subject to wear

Literature